In Connecticut, a Nanoscale Agricultural Experiment With Global Potential

The sun is strong, the sky Hollywood-set blue, but the wind is brutal. This is confounding the work of Wade Elmer, chief scientist for the Department of Plant Pathology and Ecology at the Connecticut Agricultural Experiment Station. At the CAES farm in Hamden, he and a small contingent of grad students, lab assistants, and other researchers are busy transplanting eggplant seedlings and chasing empty seed containers across the blustery, one-tenth of an acre that Elmer likes to call the “death bed.”

The landscape is unquestionably picturesque, but the field is actually riddled with soil-borne diseases, which is why Elmer, who studies these agricultural blights, has been growing sample crops here for three decades. “I’m always worried we’re not gonna get infection,” he said. “But we always get infection.”

The eggplant, to be joined later by watermelon, are components of a three-year research project by Elmer and Jason White, a toxicologist who is the Ag Station’s vice director and runs its analytical chemistry department, to test whether nanotechnology — the use of substances in extremely small form — can help plants fight disease in a way that’s never been done before. White and Elmer believe they’ve figured out how to use nutrients in nano-form to stimulate the plants’ own immune systems. No chemicals, no genetic modification — nothing that seems to be bad for the plant or its environment.

If results from the first year of the study along with three years of preliminary experiments are any indication, the researchers may be onto something. And it may represent the potential to transform agriculture broadly — and to do it cost-effectively, possibly even saving money.

The stakes are high. Estimates vary, but recent research suggests that as much as 42 percent of the global annual production of six major food crops is lost to plant diseases. In the modern age, combating agricultural blight typically has meant dousing plants in toxic fungicides and other disease-killing substances. Such treatment risks introducing chemicals into the food chain and comes with a full complement of health and environmental concerns. More recently, genetically engineering crops to survive a chemical onslaught, or in some cases so that they can resist disease on their own, has come into wider use. It’s generally effective, although some researchers — and many consumers — remain concerned about unknown risks.

The Connecticut researchers are therefore hoping that their nanotech approach might one day offer an alternative tool that would be comparatively inexpensive and easy to deploy — so much so that even developing countries facing agricultural failures from climate change, expanding blight, and other factors, may have a ready and viable option to increase productivity.

“All we’re really doing is supplying the plant with nutrients it already needs,” said White, who is the nanotech expert of the duo. “We’re just giving it to the plant in a more usable form.”

As defined by the Environmental Protection Agency, nanoscale materials are between one and 100 nanometers in size. A nanometer is one-billionth of a meter. A human hair is 80,000 to 100,000 nanometers wide.

Nanomaterials exist in nature, but are also manufactured. They’re in everything from lipstick to fertilizer, but they’ve had limited regulation based on size. Nanoscale copper, for instance, has been generally regarded the same as its larger form, commonly referred to as “bulk.” (In early January, the Obama administration published its final rule under which the EPA would regulate certain nanoscale materials, but the Trump administration delayed the rule’s implementation.)

The idea that materials would be considered the same regardless of whether they were nanoscale was a head-scratcher to White when he first stumbled into the nanotoxicology field less than a decade ago. “The whole reason we’re using a material on a nanoscale level is because it behaves differently. It has different chemical properties, different physical properties,” he said. While that might not always be true, White added, “it’s a bad assumption to assume that it isn’t.”

He saw instances in which high concentrations of certain nano-sized materials would harm plants. “But there were other instances where when you backed down that concentration curve,” he said, “all of a sudden the plant’s growing faster. It’s producing more fruit.”

What really got him from a nano-toxic to a nano-benefit mindset was an experiment in China. A researcher there had split a plant root growing hydroponically by putting half of it in a copper nano solution and the other half in an untreated solution. In the end, the copper turned up in the untreated root, suggesting that the material had not just moved up the plant, the way most materials do, but also down again to get to the untreated root.

That’s not really supposed to happen. With plenty of nutrients in the ground, plants evolved to suck them up into roots and then on to the shoots to support functions like metabolism and photosynthesis. But natural selection has dictated that most plants are unable to move the nutrients around in other directions, particularly after they are absorbed into plant tissue. The experiment in China, however, seemed to suggest otherwise — at least if the particles being absorbed are small enough.

The findings were intriguing. There are a number of nutrients plants require, including those needed in only the smallest amounts — otherwise known as micronutrients. In plant roots, some micronutrients activate enzyme systems that fight certain diseases. Copper is thought to be a key micronutrient in this regard, but the trick is getting enough of it into the roots, especially when the plant is young.

White told Elmer about the study.

“When I showed him that data, he was the most excited I’d ever seen Wade,” White recalled. “I’m thinking ‘That’s really cool,’ but Wade’s thinking, ‘Well, if I can get more copper into the roots of eggplant or watermelon or any other plant that suffers from a root pathogen, then that’s going to help that plant resist disease or fight off disease.’”

There has been plenty of research on all kinds of aspects of nanotechnology and nanomaterials, including in agriculture, but neither man could find any on the idea of using nanotechnology as a micronutrient delivery system. So they decided to do it themselves.

That was barely five years ago. Elmer knew nothing about nanotechnology when he started.

The pathogens Elmer has been after are Fusarium and Verticillium, both soil-borne fungal diseases. They affect hundreds of species, can diminish production by as much as 30 percent, and tend to stay in the soil for a very long time. Treating the soil itself isn’t the best option, because that could have all kinds of external detrimental effects, and the nutrients can disperse to places other than the plant.

Armed with the knowledge that at least some metal nanoparticles might be able to travel downward through plants, White and Elmer’s idea was to spray dissolved nanoparticle nutrients just once on the leaves of young plants. They decided on eggplant, which is susceptible to Verticillium, and watermelon, which is susceptible to Fusarium. They would compare results with applications of larger, bulk versions of the metal, which they were pretty sure would just sit on the leaves.

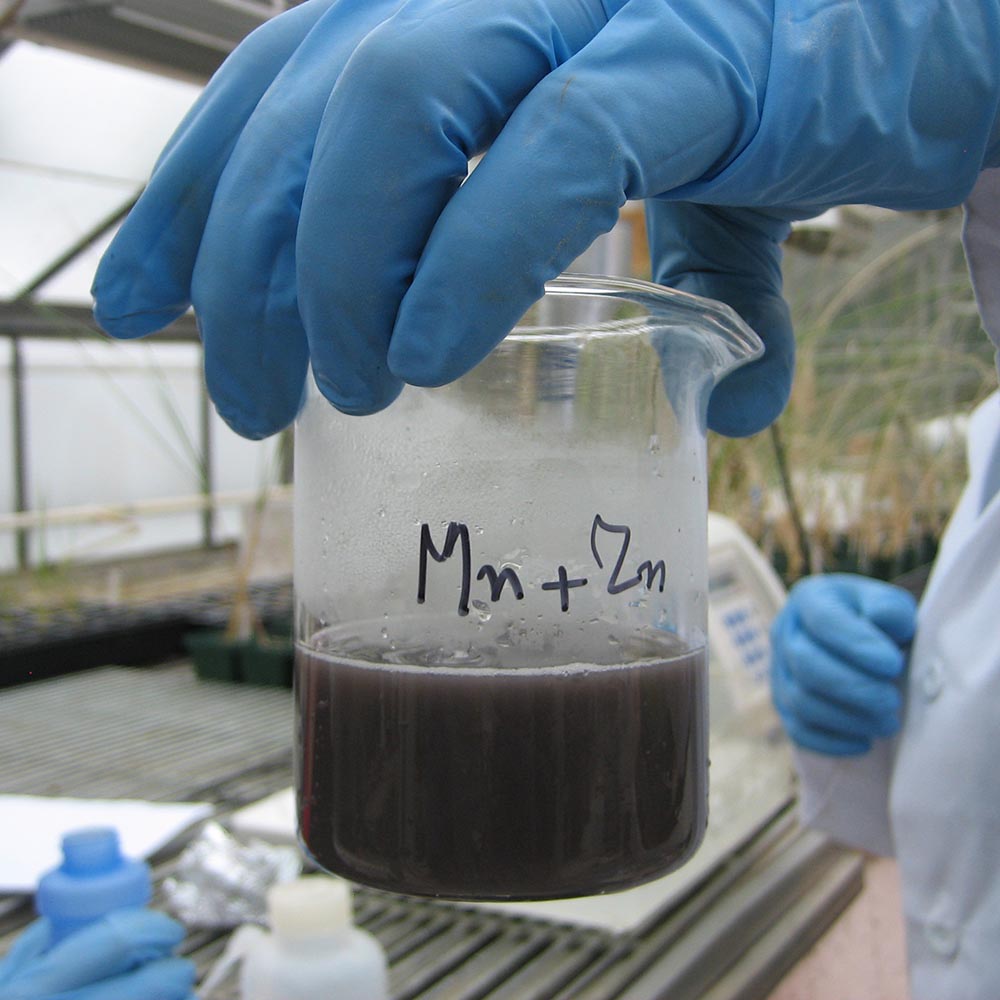

Beginning in 2013, the researchers tried all kinds of nutrients, but the main focus was copper, along with manganese and zinc – micronutrients Elmer knew the plants needed. “We found that just a simple copper spray applied on the young seedlings was translating into higher yields at the end of the season,” Elmer said.

They extrapolated that nanoparticle copper on an acre of eggplant would cost about $44, but would increase production enough to raise the value of the yield from about $17,000 to $28,000. “It was striking,” Elmer said, adding that he didn’t believe the results until he saw them repeated in subsequent experiments.

The signs were encouraging — perhaps even borderline revolutionary — but there were numerous lingering questions. Was the nanomaterial itself traveling down the plant, for example, or was it converting to an ionized form and then traveling downward? Did the nanomaterials need the presence of disease to induce the defense response? And at what point in the nutrient’s travels through the plant was the perceived benefit taking place? In the roots, or somewhere earlier along the way? Finally, and of most concern: Was the nano-metal concentrating in the edible part of the plant? If so, that would not be good. High concentrations of any number of the metals being tested could be harmful to humans.

On many of these questions, Elmer and White weren’t exactly sure. But after running experiments in 2013, 2014, and 2015 and testing for higher nutrient concentrations within the edible fruit, they at least had an encouraging answer on that front: “We found none,” Elmer said.

Indeed, the results broadly showed that eggplant treated with nanoparticles fared batter in a variety of ways than eggplant treated with bulk versions of the same nutrient. In greenhouse experiments, plants getting nano-copper or zinc had increased weights. A field trial of eggplant in 2013 showed that yield was higher in plants treated with nano-versions of copper or manganese. A repeat field experiment in 2014 showed the same, with nano-zinc also producing higher yield. Both manganese and copper showed larger canopies.

Watermelon experiments showed nanoparticle copper produced greater yield and less disease, and nano-copper concentration was far higher than bulk versions of the metal in watermelon roots.

A drought during the summer of 2015 depressed all results in the field trials, so that year is not considered indicative of any particular trend. But Elmer said he thinks the nanoparticle itself is moving down the plant — a process known as translocation. Knowing what’s happening inside the plant will ultimately help determine the safest, most efficient, and inexpensive ways to develop commercial products to treat plants, but Elmer and White are still far from figuring that out.

“We took great care to make sure none of it got onto the roots,” he said of the treatment — a crucial step to ensuring that what was being detected in the root had travelled down through the plant, rather than being taken up by the roots.

Whatever was happening, it was compelling enough to win White and Elmer a $480,000 U.S. Department of Agriculture grant for the big three-year study that began last year.

Most nanotechnology researchers contacted were unfamiliar with White and Elmer’s approach of using nanotechnology to deliver nutrients to stimulate a plant’s own immune system.

“That’s really interesting,” said Patricia Holden, a professor and nanotech researcher at University of California, Santa Barbara’s Bren School of Environmental Science and Management. She said she’d like to know whether the particles found in the root are still intact, if they’re entering the soil, and what sorts of metabolites are being produced in the plant. For edible varieties, the issue is safety. The results might show more, bigger, and disease-free fruit, but until it’s clear what’s actually going on inside, it’s hard to know whether the plant is safe for human consumption.

Christine Hendren, executive director of Duke University’s Center for the Environmental Implications of Nanotechnology, cautioned that there’s still little certainty that nanomaterials aren’t congregating in plants that may then be transferred to an animal that eats them, passing them on through the food chain. And there is no clear understanding of other unintended consequences of introducing nano-metals to the environment. “Companies don’t know if it’s safe to develop this,” she said, “or will we be stuck with legacy-type, asbestos-type problems?”

On the other hand, the approach could avoid what she called the “massive toxic dump” way of doing things currently, in favor of what she called “the plant equivalent of personalized medicine.”

Other researchers noted similar agriculture and nanotechnology studies focusing on ways to improve fertilizer delivery, lower the need for pesticides, directly target diseases, and especially make crops more drought resistant as the climate changes. “It’s a very straight connection with climate change in my opinion,” said Mariya Khodakovskaya, a professor at the University of Arkansas who has been looking at ways to use carbon nanomaterials to help plants use less water.

“We can use nanoparticles as one-stop shopping,” said Christian Dimkpa, a plant and soil biology research scientist with the International Fertilizer Development Center. He has been experimenting with several nanotech techniques for crops important to his native Nigeria. “That means using it to address multiple plant problems — including disease, including growth, including yield, and including resistance to environmental aspects such as drought.”

The climate change potential is paramount for White, who noted that both he and Elmer have received queries from researchers worldwide, many of whom are eager to participate in their research, or figure out how to do their own. The stakes are particularly high as global temperatures creep ever upward. “We’re going to need to grow crops on more marginal lands under more marginal conditions,” White said. “So if we can come up with a way to make that easer to do, then I think that’s tremendous.”

For now, though, much more research needs to be done.

A week or so before the very windy day in the death bed last summer, the action was all in New Haven at the greenhouse on the Ag Station’s main campus. The station was the nation’s first such facility, with the creation of the hybrid that revolutionized commercial sweet corn, the identification of Lyme disease, and the first North American isolation of West Nile virus among its accomplishments.

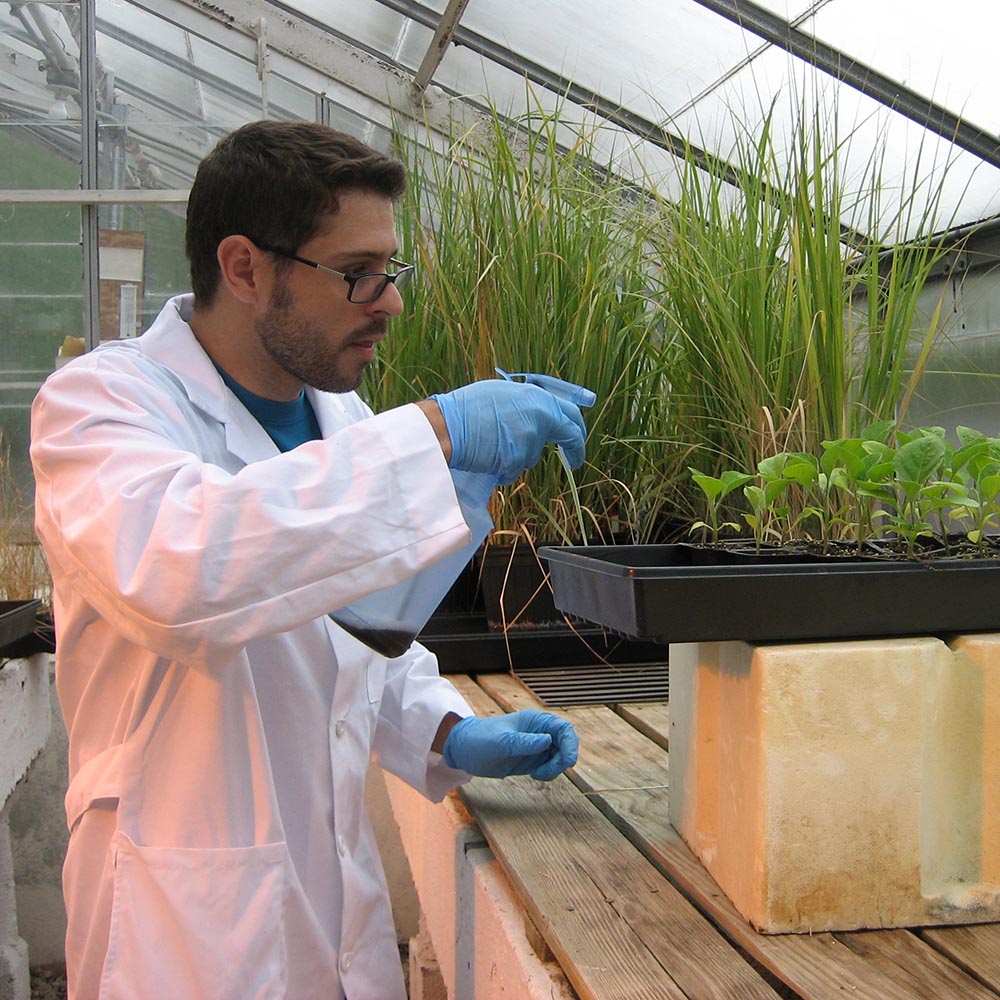

Roberto De La Torre, a postdoctoral researcher, sprayed eggplant seedling leaves with nine different treatments of nanomaterials: copper, manganese, zinc, cerium, copper/zinc, copper/manganese, manganese/zinc, copper/cerium, and copper/manganese/zinc. A control received no treatment. White and Elmer saw no point in using bulk nutrients given the definitive results of their earlier experiments.

Each treatment was a 500 parts-per-million solution in tap water plus surfactant to help it stick to the leaf. There were six replicates of each treatment and each replicate was composed of three plants that would be averaged together for statistical purposes. Total eggplants eventually in the ground: 180.

During the growing season, the plants were checked regularly to monitor for disease, and their canopy was measured with a decidedly low-tech tape measure. “We always feel that’s one of the best reflections of health,” Elmer said. “You can look at the plant and say, ‘Oh, there’s 10 percent disease.’ But you come back tomorrow and there won’t be any disease because those leaves have just fallen off.

“But if you look at the canopy,” he continued, “that takes in account the size, but also the defoliation of those leaves.”

As eggplants were harvested, their reference numbers were written onto the necks, and the yield by treatment was measured. Copper-sprayed plants showed a yield by weight that was 17 percent higher than the control group. Those sprayed with manganese did nearly as well. The combination of copper, manganese, and zinc, however, showed a whopping 31 percent increase over the control.

“I don’t know,” Elmer said, when asked why.

More sophisticated measurements were planned for how much of each nutrient treatment might have been left in the plants’ leaves, roots, stems, and fruit — the big one being the fruit. “That’s always the first question,” White said. “If you’re treating a food crop with nanoparticle copper and you’re finding lots more copper in the fruit, that might not necessarily be a good thing even if you did suppress disease and got better yield.”

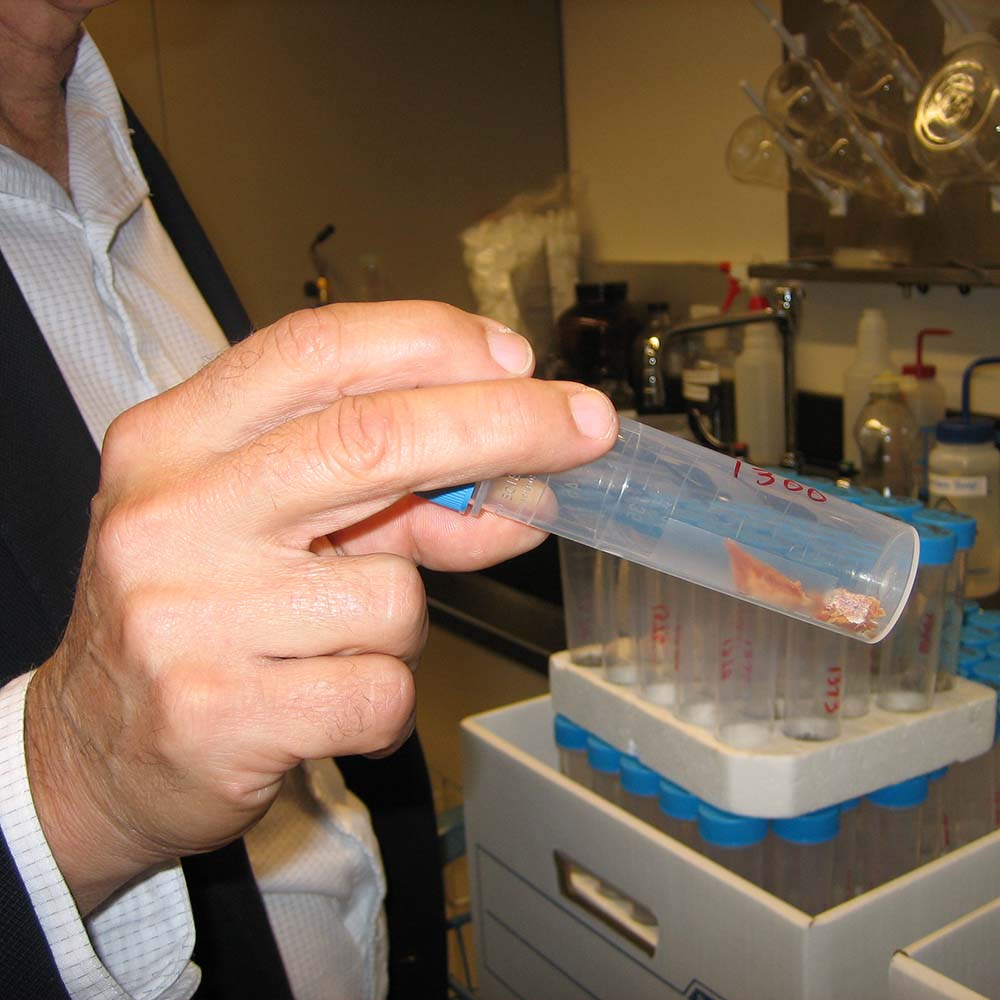

Those measurements involve three stages of increasingly specific testing starting with taking tissue from the four parts of the plants. Each sample was dried and ground to a fine powder — a Mr. Coffee coffee grinder being the preferred implement. The powdered samples were dissolved in nitric acid and hydrogen peroxide heated to 110 degrees Celsius for two hours and processed through an inductively coupled plasma mass spectrometer (ICPMS). The device can determine whether the elements in question are there, and if so, how much. But it can’t tell you whether the nutrient is in nano or some other form.

More than 800 samples were tested from the 2016 eggplant and watermelon harvest. The biggest news was that in copper-treated eggplant, copper levels in the fruit were actually lower than in the control group. But copper was 14 percent higher in the fruit of the eggplant treated with all three micronutrients, and manganese was 15 percent higher in the manganese treated group.

Elmer cautioned that because the concentration levels were an average of all the plants in each treatment group, there might be less overall statistical significance, since concentrations tended to vary from plant to plant. In some instances, manganese and zinc were found to concentrate in the leaves, and zinc tended to concentrate in roots. But most other measures showed statistically insignificant changes.

The eggplant study is being repeated this summer along with nanoparticle testing on pumpkins, soybeans, wine grapes, and strawberries.

In addition to the ICPMS, analysis will be done through electron microscopy using a scanning and transmission electron microscope that can greatly magnify the surfaces of the plant, look inside the cells, and determine the elemental composition of what’s inside. It requires slides from thin slices of fresh tissue — the big caveat being that researchers won’t know if they have the “right” slice.

The most precise level of testing would eliminate that problem because it gives a three-dimensional view of an entire plant, what’s in it, and where. But it requires a synchrotron — an extremely sophisticated and expensive piece of equipment. There are only about 60 in the world, and the team has not yet secured a grant to use one.

In the meantime, with the planet facing fast-evolving agricultural blights, excessive use of chemical pesticides, depleted soils, changing climate conditions, and swelling populations in need of food, Elmer and White both remain hopeful, even giddy, that they just might have stumbled onto something that can help — and something with potentially global implications.

“You take it to sub-Saharan Africa and you work on wheat, millet, on stressed soils, or you go to central Asia and you start talking about rice,” White said. “That’s what excites me.”

Jan Ellen Spiegel is a freelance writer and editor based in Connecticut. Her work appears regularly in numerous local and national publications, including The Connecticut Mirror, InsideClimate News, Yale Climate Connections, and The New York Times.

Comments are automatically closed one year after article publication. Archived comments are below.

This just proves that soil health is very important to the growth of whats planted. Monoculture will be the death of us. We have the capability along with ingenuity to grow food without resorting to monoculture. Current practices only ensure pest dominance developing resistance to any pesticides we continue to manufacture. Natural predators will continually avoid areas sprayed with pesticide creating pest dominance. I know we are capable of creating a way of farming that integrates practices that serve both our needs while weaving these to be harmonious to the fundamental aspects of nature.

There is a quote for which I’m very fond of and it is ,

“We are never moved to search for answers for which we already believe we know the answer” ..

I am completely AGAINST any form of ‘genetic’ modification. Whatever excuses you come up with are crap! Humans actually believe that whatever THEY decide to do is OK for the rest of our fellow creatures on this planet. NO. Nature Bats Last. You can genetically alter whatever you want to and believe that ‘humans’ are the smartest creatures on the planet, but you will be incorrect!! Once ‘man’ has devastated this planet and go off to kill another planet, THIS planet will slowly regenerate itself into what the PLANET needs. The planet doesn’t NEED people, but people need the planet. We need to learn to live WITHIN this natural system NOT human-manipulate it!! Quit!!!

I don’t think this is quite genetic manipulation. I agree with you in the sense that we should be cautious about the concentration of metal especially in the fruit itself. Also, I think we should work on correcting the problem of climate change rather than spending all our time preparing to live in a world affected by climate change; however there are real world obstacles we must face.