Meet the Weed Seed Pulverizing Machine

On a cold, clear day last November, a combine lumbered through a soybean field in Beltsville, Maryland, towing a bulky-looking gray and red machine like a caboose. With each pass, the combine separated the beans from their hulls and then directed plant waste into the smaller contraption, which pulverized the chaff and then shot it back onto the field in a steady stream of dust.

The roar from the farming equipment was deafening — like standing on a busy airfield — and Steven Mirsky, a talkative ecologist with the United States Department of Agriculture, shouted inaudibly over the din.

Steven Mirsky, an ecologist with the USDA, has sought practical solutions to the weed paradox for more than a decade.

Visual: Annie Klodd

Known by a name seemingly out of a superhero comic book, the Harrington Seed Destructor is a mechanical beast that takes aim at a tiny but formidable enemy: the seeds from crop-destroying weeds. They plague farmers the world over, and left unchecked, weeds would cost an estimated $43 billion in lost soy and corn production alone in the United States and Canada each year.

To fight back, most farmers have two main choices, at least for now: rip the weeds from the ground by hand or by plow, or spray them with chemical herbicides so they wither and die. But these choices have long presented a paradox. Tilling can control weeds, but it also can disrupt and degrade the soil — and poor soil grows poor crops. Herbicides, on the other hand, are easier to use — just point and spray — and they can preserve the soil’s delicate structure. But just like bacteria exposed to too many antibiotics, weeds confronted by years of herbicide spraying can give rise to resistant varieties that are increasingly hard and expensive to kill.

Today, in fact, there are more than 250 species of weed that are resistant to at least one key herbicide ingredient on the market, according to the International Survey of Herbicide Resistant Weeds, a coalition of weed scientists in over 80 countries. And according to data from the U.S. Environmental Protection Agency, companies don’t have many new herbicides in development.

That’s where Mirsky and the Harrington Seed Destructor, or HSD for short, come in. Mirsky — who manages around 100 acres at the USDA’s Agricultural Research Service station in Beltsville, and whose bubbling energy seems perpetually stuck on 11 — has sought practical solutions to the weed paradox for more than a decade. One of his goals is to go after the seeds, when weed populations are especially vulnerable, rather than trying to control weeds that have already taken root. The approach “has been kind of a dream for the weed science community,” he says.

But weed seeds are wily — some plants can produce hundreds of thousands, which spread quickly across a field. Until recently, there hasn’t been a machine that’s been able to tackle weed seeds on a large scale, where farms with “five, ten thousand acres could go, not blink an eye, hit their fields and keep on going,” Mirsky says.

In 2014, at the annual Weed Science Society of America conference in Vancouver, Canada, Mirsky saw a group led by Australian scientists present research on the HSD, which smashes the delicate reproductive machinery inside of weed seeds to leave them impotent. “Wow! This awesome!” he remembers thinking. “This is what we need to be doing.”

Of course, no machine will solve all of farmers’ weed woes, and taming the pests and plagues that threaten our food takes a diverse set of tools. But Mirsky and his team — which includes Adam Davis, a USDA weed ecologist in Urbana, Illinois, and Jason Norsworthy, a weed scientist at the University of Arkansas — do see the HSD as the cornerstone of an ambitious five-year project that spans 17 research centers in 13 states. Instead of emphasizing chemical spraying alone, the researchers want to use a multi-faceted approach, termed by weed ecologists Matt Liebman and Eric Gallandt as “many little hammers.” Success will mean not just finding the best suite of tools to kill the weeds, but also convincing farmers to change their habits.

“Every farmer needs to be thinking about how to do this now,” Davis says. “There is no path forward for chemical-alone weed management. We have to reduce our reliance on herbicides because there’s nothing new in the pipeline.”

The newest version of the Harrington Seed Destructor is now getting attention from farmers worldwide. And if the machine can effectively chomp the seeds of the right species of weeds; if enough farmers incorporate weed seed control into their land management plans; and if a tempting new chemical doesn’t come along to start the herbicide cycle anew — then the HSD just might work.

Farmers have been tussling with herbicide resistant weeds for at least 60 years. The first widely used synthetic auxin herbicides, which mimic plant growth hormones, appeared in the 1940s. By 1957, farmers in Hawaii found auxin-resistant dayflowers creeping into the sugarcane, and Canadian fields broke out with auxin-resistant wild carrots.

The reason is simple and inevitable: evolution. Herbicides put an artificial selection on weeds, and the more farmers use the chemicals, the higher the pressure for the plants to evolve. Herbicides don’t necessarily kill every weed in a field. Some have the genetic constitution to survive and spread their vigor to a new generation.

But in some regions, resistance has run amok. This is particularly true for the herbicide glyphosate, the main ingredient in the product Roundup. Monsanto launched the chemical in 1974. Twenty years later, the agricultural company introduced its first glyphosate-tolerant GMO seeds, which it genetically engineered to make crops immune to the herbicide. These “Roundup Ready” seeds allow farmers to spray glyphosate on corn, soy, and cotton to kill weeds without worrying about killing the crops in the process — a faster, easier approach that also leaves the topsoil intact.

In 1994, Farm Chemicals magazine proclaimed the herbicide among the “top ten products that changed the face of agriculture.”

Critics have pushed back against herbicide-tolerant GMOs and glyphosate over the years. Some concerns are environmental, such as the increase in glyphosate use that has led to more resistant weeds. Others are over health, particularly of farm workers who have regular exposure to the chemicals, although the science is mixed and highly politicized. Still, the seeds remain popular. In 2016 in the U.S., they made up 94 percent of soybeans, 89 percent of cotton, and 89 percent of corn.

But the seeds’ popularity have contributed to glyphosate’s downfall. Fans of the technology rightly point out that GMOs aren’t directly responsible: Genetic engineering itself doesn’t drive resistance. But widespread use has led to an over-reliance on glyphosate. “Wow, why are we in this situation?” Mirsky says. “Well, one of the most Cadillac practices that we’ve developed, that is the most important [soil] conservation strategy of our time — no-till agriculture — is a big part of why we are seeing this resistance.”

Worldwide, there are now at least three-dozen weed species with glyphosate resistance — a figure that experts expect to grow. In the U.S., the most infamous is arguably palmer amaranth, a type of pigweed. Farmers reported the first glyphosate-resistant palmer amaranth in Georgia in 2004. Now it’s found in 27 states.

Palmer amaranth’s other nickname is carelessweed, but even careful farmers find it a formidable foe. Glyphosate kills most weeds by targeting the synthesis of a protein necessary for plants to live. Plants usually have one or two copies of the gene that makes this protein. Not so with glyphosate-resistant palmer amaranth: In 2010, scientists at Colorado State University showed that the weeds have between five and 160 copies of the gene, which means they can pump out more of the protein and are harder to kill.

These superweeds present “a really interesting case of evolution,” says Todd Gaines, a weed scientist at Colorado State and the lead author of the study. The genetic tweaks in the plants are akin to how certain cancer cells evolve resistance to drugs, or how some insects thwart insecticides. But the palmer amaranth, says Gaines, marks “the first time this type of rapid evolution for increased copy number has been observed in plants.”

Even worse, the weed is unusually prolific: A single palmer amaranth spawns between 500,000 and one million seeds. “Even if there is just one in ten million that survives, that’s a tremendous amount of seed,” Gaines says.

Resistant weeds have driven some farmers out of business. Others are plowing the weeds under, despite the wear and tear on the soil, and still others have returned to the backbreaking practice of pulling up weeds by hand. In Georgia, for example, the majority of cotton farmers hire laborers to rip herbicide-resistant palmer amaranth from half their fields, says Stanley Culpepper, a weed scientist at the University of Georgia.

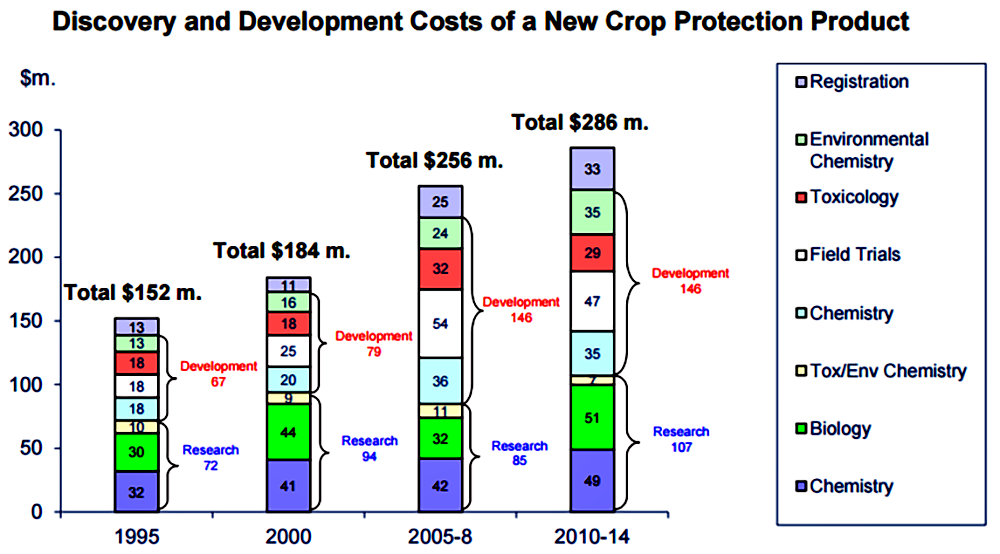

Although agrochemical companies have tried to find the next blockbuster weed killer, it has proven difficult to find novel chemicals that work. Pesticide research is also expensive: According to CropLife, an industry group, research and development for a single active ingredient costs $286 million and takes 11 years. But the companies’ next-best solutions still usually involve chemicals. One option is to mix multiple herbicides together. If each kills in a different way, a weed is less likely to resist them all. A 2015 study from the journal Pest Management Science, which compiled data from 105 central Illinois grain farms from 2004 to 2010, found that combining glyphosate with other chemicals significantly delays resistance, but won’t likely prevent it.

Companies that develop GMO seeds are also engineering new versions that tolerate multiple herbicides. Dow, for example, has new seeds that tolerate glyphosate and 2,4-D, an herbicide that has been around since 1945. Monsanto has a similar product, only with glyphosate and dicamba, an herbicide that dates to 1967. Here, the concept is similar: use a mixture of chemicals in the hopes that weeds will succumb to at least one. The technology “provides you a lot of comfort and barrier for resistant development,” says Robert Fraley, the chief technology officer at Monsanto.

But mixes of old chemicals won’t necessarily help, says Carol Mallory-Smith, a weed scientist at Oregon State University. In some cases, the chemicals already face significant resistance — 2,4-D, for example, is an auxin, the chemical class that sparked the first herbicide-resistant weeds six decades ago. The chemicals are also typically effective against different types of weeds. Glyphosate kills both grasses and broadleaf plants, for example, while dicamba and 2,4-D are only effective against the latter. This could lead to more glyphosate-resistant grasses. “This is not going to, in my opinion, be any kind of solution,” Mallory-Smith says.

Meanwhile, farmers are desperate. In 2016, Monsanto released one of its new glyphosate/dicamba seeds — a soybean. But there was a catch. Dicamba is light, and it’s infamous for drifting on the wind and landing in places it wasn’t meant to be. Monsanto developed a new formula to help control the drift, but regulatory approval for the new seed came through before approval for the new herbicide. The company decided to sell the soybeans anyway, warning farmers not to use the seeds with the old dicamba formulas already on the market.

But some farmers ignored the warning and their dicamba drifted to nearby farms. Some of these farms hadn’t planted with the new dicamba-tolerant seeds, and the illegal sprays damaged an estimated 200,000 acres. And in one extreme case, a dispute over dicamba between two farmers on the border of Arkansas and Missouri ended when one shot the other dead.

Over the past several decades, deep in sheep country in Western Australia, a parallel tale of herbicide resistance has played out. But this story has a different ending.

Around 20 years ago, a sheep farmer named Ray Harrington decided to sell his flock of 12,500 and convert his land to crop production. At the time, the price of wool, a staple in the Australian economy, was dropping. “I knew I was going to go broke,” Harrington says. “I knew that if I didn’t do something real quick, then I was gone.”

Inventor and Australian farmer Ray Harrington said he was going broke trying to deal with herbicide-resistant weeds.

Visual: Australian Herbicide Resistance Initiative

But Harrington also knew he’d have to approach his new venture strategically. Other farmers in his region had been swapping their livestock for grain for years, leaning on herbicides to help control weeds. This gave rise to an ornery strain of ryegrass, an invasive plant originally used as forage for the region’s flocks of sheep. But thanks to widespread herbicide use, the ryegrass evolved a metabolic form of resistance, meaning it could guzzle up pretty much any herbicide and still survive —like a heavy drinker who has developed a high tolerance to any brand of booze.

“We had two farmers in Western Australia who had the worst herbicide resistance in the world,” Harrington says. He knew “herbicide resistance was here, it was alive and well, and it was going to smack us.”

Harrington, an avid inventor who has co-authored two patents, knew he needed an alternative to chemicals. He also knew he wanted to strike weed seeds, before they could spread across his fields.

In wheat fields, weed seeds spread especially well at harvest. Wheat farmers use combines, which separate the grain from the chaff and spew the latter back onto the fields. The intention is to spread the chaff in a thin layer, because thick banks of plant waste would make it harder to grow next year’s crop. When a combine picks up weeds during the harvest, it becomes an unintentional reproductive aide, flinging fecund seeds farther than they’d likely go on their own.

Harrington decided the best option to fight the seeds was to catch and destroy them before the combine expels its chaff. He considered his options, which he now calls the Big C Project. The C stood for chaff, as well as what he planned to do with it: catch it, cart it, crush it, cook it, or cremate it.

Existing technology addressed some Cs already. Chaff carts, for example, tow behind combines to collect plant waste, which farmers burn or feed to livestock. Then there’s narrow windrow burning, where combines drop chaff in long, concentrated piles that are easy to cremate. After mulling the possibilities, Harrington decided to try something new: catch and crush.

Harrington envisioned using a mill. It took two years to find a contender: a cage mill used in the mining industry to burst fist-sized lumps of coal into a fine talcum-like dust. The mill destroys by impact, rather than grinding. “It’s a bit like you drive down the road and you run into a plague of locusts,” he says. If you’re going just a few miles per hour the locusts “hop off the window with a few broken legs.” But if you’re speeding at around 70, “they all go splat.”

The mill, Harrington hoped, would splat ryegrass seeds hard enough to destroy the embryo inside, sterilizing them.

Harrington commissioned a cage mill to try at his farm. He fed ryegrass seeds through it, and then tried to plant them. Nothing grew.

Harrington wasn’t quite sure what to do next, but in 2004 he had a breakthrough: a chance encounter with Stephen Powles, director of the Australian Herbicide Resistance Initiative and world-renowned weed guru. Within days, Powles invited Harrington to bring the crushed seeds from his machine to the University of Western Australia for analysis. Harrington says it was the first time he stepped foot on a university campus.

In the coming years, the men struck a partnership. Powles committed $20,000 out of his research budget to help Harrington and a friend, a retired farmer, build the first prototype: a cart fitted with a mill, designed to tow behind a combine to catch and destroy weed seeds.

Powles and his colleagues, including Michael Walsh, a weed agronomist now at the University of Sydney, tested the machine in wheat fields, as well as on barley and lupin, and found that it consistently crushed 95 percent of ryegrass seeds. It also destroyed 93 percent of seeds from wild radish, and 99 percent of both wild oats and brome.

For Powles, the Harrington Seed Destructor fit into a larger system he’d been working on his entire career — an attempt to nudge herbicides from center stage. While his approach includes targeted herbicide sprays, he also promotes smart agronomy, such as strategically planting crops close together so that when they grow tall enough their canopy blocks weeds from sunlight, and crop rotation, which helps break up pest lifecycles.

Whether Powles’s approach will take off in the U.S., though, is unclear. Since 2005, he has traveled to North America at least once a year to talk to farmers and scientists about herbicide stewardship and weed control. Last May, after his most recent trip, Powles still has the impression that “the U.S. farmer and all those that advise them are pretty much hooked on herbicides. They find it difficult to look past herbicides as the only solution to the problem.”

While there are researchers willing to try something different, he says “the reaction of most is to reach for the next jug. And it doesn’t have to be that way.”

The Harrington Seed Destructor in action at the University of Illinois in 2016.

After the Vancouver conference, Mirsky went about figuring out how to get an HSD — which is made only in Australia and, at the time, cost $250,000 — to the U.S. to test on palmer amaranth and other weeds. That spring, he was sitting in his office on a sprawling campus in Beltsville, a series of formal brick buildings nestled into rolling farmland, when he landed on a solution.

The USDA’s Agricultural Research Service announced it was seeking applications from USDA scientists for a nationwide agricultural weed control project. “It kind of just dawned on me as I was sitting in my office. I was like, you know what? This is the perfect program for really moving the HSD — and more importantly, moving integrated weed management — and putting it together at a national level,” Mirsky says. “This is the perfect tool, this is the perfect system.”

The HSD may be a good tool, but Mirsky had to rethink the scope of his original idea to qualify for the funding. The program aims to develop technology that is useful for farmers who can’t tackle a problem on their own, to help control pests with wide ranges that cross the arbitrary invisible borders between farms.

In order meet the program’s requirements, a successful proposal must address not only the technology and science, but also “what’s needed among local government, federal government, farmers and universities” to make it a community-wide effort, says Rosalind James, the national program leader. In other words, Mirsky needed to think bigger.

Thinking bigger wasn’t exactly a stretch. When Mirsky describes his work, he pushes his words out at such a clip that he almost runs out of breath. “Herbicides are part of the story, sure. But so is crop rotation. Tillage. Cultural practices like planting date, seeding rates, row spacing. Precision nutrition management — feed the crop and not the weed. Cover crops.”

It’s an ambitious list. But to tackle at least some of it, Mirsky and his collaborators came up with a plan: three research hubs to test the HSD and incorporate it into long-term cropping systems, plus several satellite sites to work on crop rotation and other complementary tactics. Mirsky and Davis, his collaborator in Illinois, would each get an HSD to run in the field, while Norsworthy in Arkansas would get a stationary HSD mill to test in the lab.

Even though the HSD works on ryegrass in Australian wheat fields, each new field presents a new challenge. Plants have unique biological cycles. They drop their seeds at different times, and those seeds have their own suits of armor to protect the embryos inside. In order for the machine to work, a weed must hold its seeds at least until harvest time — otherwise, the combine won’t pick up the seeds or run them through the mill.

“Harvest seed management is a cool technology in general. But it also requires a lot of knowledge of basic biology of the weed seeds and crops, to know if it’s going to work,” says Andrew Kniss, a weed scientist at the University of Wyoming.

“And basic biology is probably the least fundable part of weed science right now,” he adds.

Mirsky’s team is addressing this problem by testing the HSD on more than a dozen species of weeds. The researchers will run the HSD in wheat, corn, and soybean fields in 15 states in the south, mid-Atlantic, and upper Midwest, to see if the harvest times catch the weeds before they’ve released their seeds. They are also running weed seeds through the machine to see how effective it is at smashing the hulls. Preliminary results suggest that the mill can destroy 99 percent of seeds from the dreaded palmer amaranth, as well as common waterhemp, common lambsquarters, giant foxtail, velvetleaf, ivyleaf morning glory, giant ragweed, and common cocklebur.

The remaining one percent of the seeds could be a problem. Any survivors may mean that the HSD itself can drive resistance by encouraging weeds to adapt to drop their seeds early, or otherwise evade the machine’s deadly mill. A 2016 study on the effects of weed seed control on wild radish found that the weed could alter the timing of its flowers and seed production. “I definitely think weeds can evolve resistance to the HSD, most likely by flowering earlier and setting seed,” says Michael Flessner, a weed scientist at Virginia Tech who is part of the team. “We’ve just started to look at this, so we don’t have any results yet.”

The final piece of the project is to see how the HSD integrates with other systems. The researchers will use the machine in Maryland, Illinois, and Arkansas along with cover crops and various herbicide treatments — which will still be necessary, although in comparatively small amounts — to see how the combined approach affects herbicide resistance in weeds.

But plant biology and agricultural logistics are only part the challenge. Even if the HSD can destroy the countless millions of palmer amaranth seeds shooting out the back of combines across the U.S., it won’t matter unless farmers decide to use it. And to do that, Mirsky’s team has to show the investment makes financial sense.

To tackle this, the USDA project will lay out the basic economics of the seed destructor to see how long it will take for it to pay for itself, and build a model for managing a patchwork of land with multiple owners and porous borders.

“One of the critical research questions is: How many people need to actually participate over a landscape to be effective enough?” says George Frisvold, an agricultural economist at the University of Arizona who is working on the project. Frisvold and David Ervin, an environmental economist at Portland State University, plan to use models adapted from the Nobel-winning political scientist Elinor Ostrom, whose work shows how communities can successfully manage collective land.

“You can’t answer it with just economics, or just the biophysical. And that’s the problem we’re trying to surmount.”

But to even get to that point, Mirsky needed the Harrington Seed Destructor. He placed the order in the summer of 2014, and by the time it arrived a year later, the machine was already obsolete — the patent holder, Grains Research & Development Corporation, funded the University of South Australia to develop a new model that integrates into a combine, a cheaper and more attractive investment for most farmers.

The mills in the different models, however, are virtually the same, which meant the old version would suffice for Mirsky’s work. In 2015, the Australians loaded an HSD on a cargo ship in Melbourne, where it started a month-long, 10,000-mile journey to Baltimore. From there, a trailer hauled the machine to Beltsville. When it arrived, Mirsky realized the HSD was so big he had to hire a crane and operator to lift it from the trailer and set it gently on the Maryland soil.

Standing next to the machine for the first time “was a thrill,” Mirsky says. “It was a real big beast.”

When Mirsky had the HSD out in Beltsville last November, it was the first week he’d been able to run the machine thanks to a series of unexpected technical hurdles. His team had to fumble through these alone, because the company that licenses and sells the equipment, de Bruin Engineering, phased out production and service on the older model.

Combines come in an array of shapes and sizes, and the older HSD didn’t automatically fit them. Mirsky’s farm crew had to adapt the machine to their combine, which took a series of welding experiments over the course of several months. The team also had to reinforce the combine to support the HSD’s six-ton weight.

“The thing just sat for a year [in a pole barn,]” Mirsky says. The process to get it running “was exhausting and ridiculously painful.”

“But we’re here! We’re good! I’ve worked out all the kinks.”

Those kinks worked out just in time: November was the last opportunity to harvest for the season. If the beans stayed in the field much longer, they would rot, and Mirsky would have to wait until summer to start collecting new data.

Mirsky squinted in the sunlight and grinned as the combine dragged the HSD across a row of beans. His team tests a lot of farm prototypes, which often aren’t quite field-ready. Once it was finally on the back of a combine, the HSD, though, was a natural.

“When you watch it in the field, it’s crazy,” he shouted over the jet-engine rumble of the machine. “Because to me, it looks like it belongs there.”

Brooke Borel is a New York-based science journalist and a contributing editor at Popular Science magazine. Her work has also appeared in The Atlantic, The Guardian, BuzzFeed News, Slate, and PBS’s NOVA Next, among other publications.

Comments are automatically closed one year after article publication. Archived comments are below.

The Harrington Seed Destructor has more definet weed control of weeds than any other system

made in the world today, hopfully big brother and its money, does not kill the great oppertunity that a hard working West Austalian farmer started many years ago.